Engineered Connections

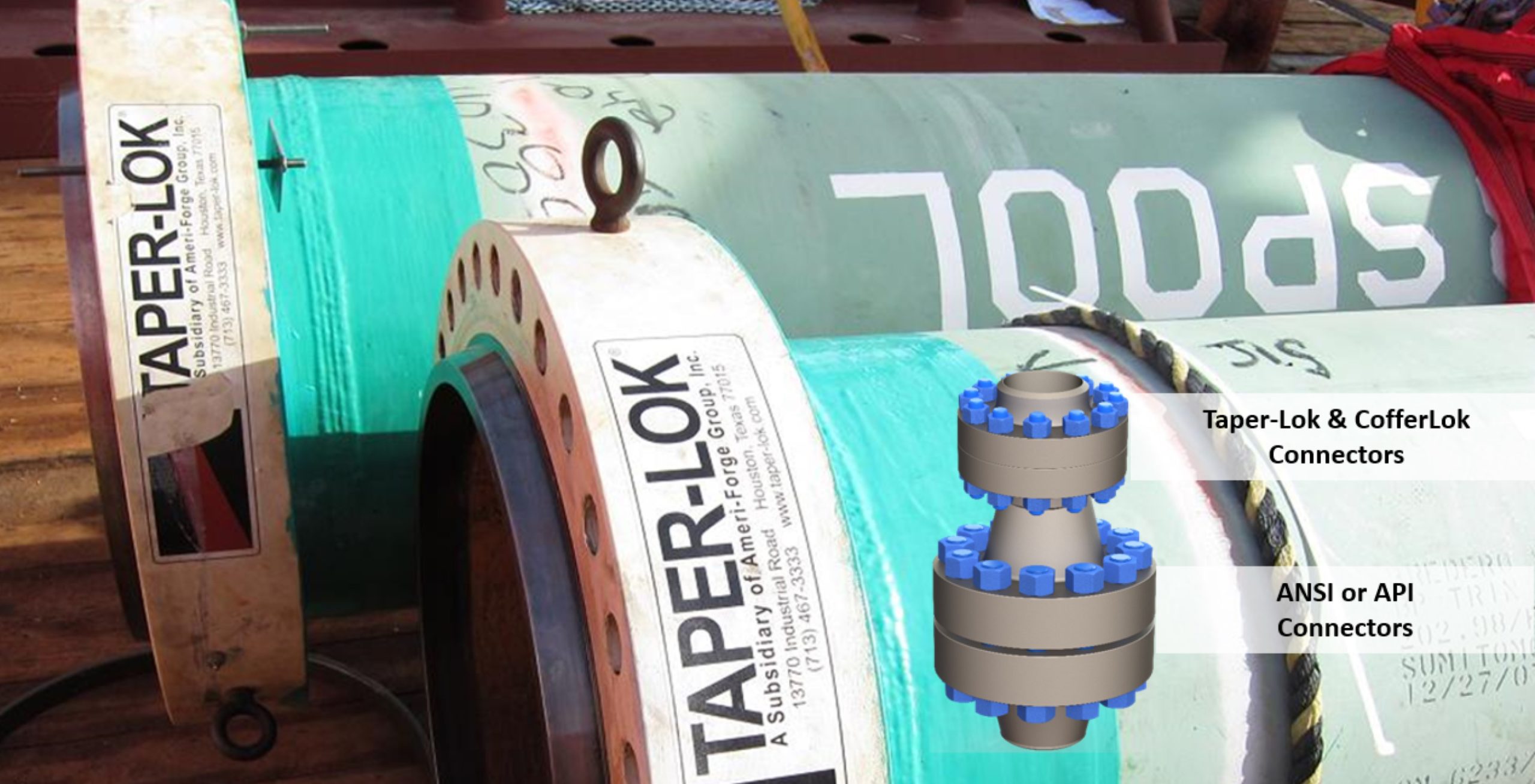

Our Engineered Connection Systems provide the solutions to chronic problems associated with standard ANSI and API flange connections. Applications for our connectors include offshore topsides/hulls, subsea risers, subsea and onshore pipelines, downstream petrochemical/refinery, aerospace and heat exchangers.

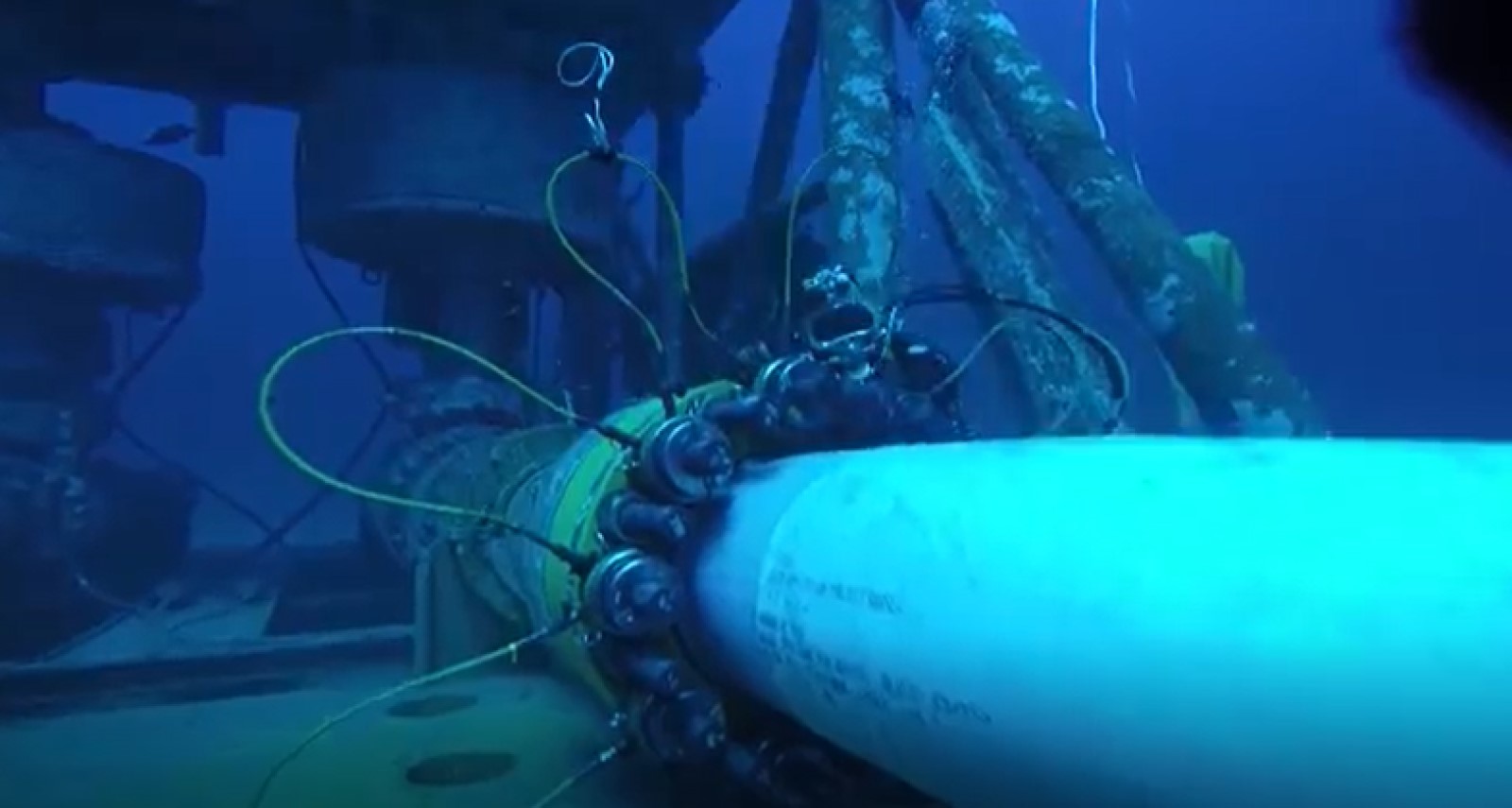

Diver Connections

Engineered connector benefits include: Leak-free reliability, weight/space savings, external loads, quick assembly, cost savings, misalignment capability and use in high pressure/temperature applications.

Subsea & Risers

Diver-friendly, Taper-Lok swivel and weld neck flanges can come with a spherical nose configuration on the male flange, which allows for 2-3 degrees of misalignment. Installs up to 75% faster than API flanges

Topsides & Hulls

With weight savings of up to 80% in comparison to ANSI flanges, our engineered connection systems can typically save up to one million lbs.on offshore floating platform topsides.

Petrochemical & Refinery

Our Engineered connectors have metal seal technology that thrives in critical services where standard ANSI or API flanges tend to have leak issues. If leak-free reliability is important in severe applications with erosion/corrosion and/or high pressure/temperature processes, then Taper-Lok and CofferLok connectors are a must.

Heat Exchanger Connectors

Permanently eliminate leaks at the welded diaphragm

Whether you are designing a new build exchanger or need to retro fit an existing one, Taper-Lok® seal rings on the channel cover and tubesheet are the superior choice. Our customers can typically save up to $400K each planned shutdown for each exchanger. Customers can also potentially save $Millions in lost production during planned shutdowns due to less cost for parts, service and less days of downtime.

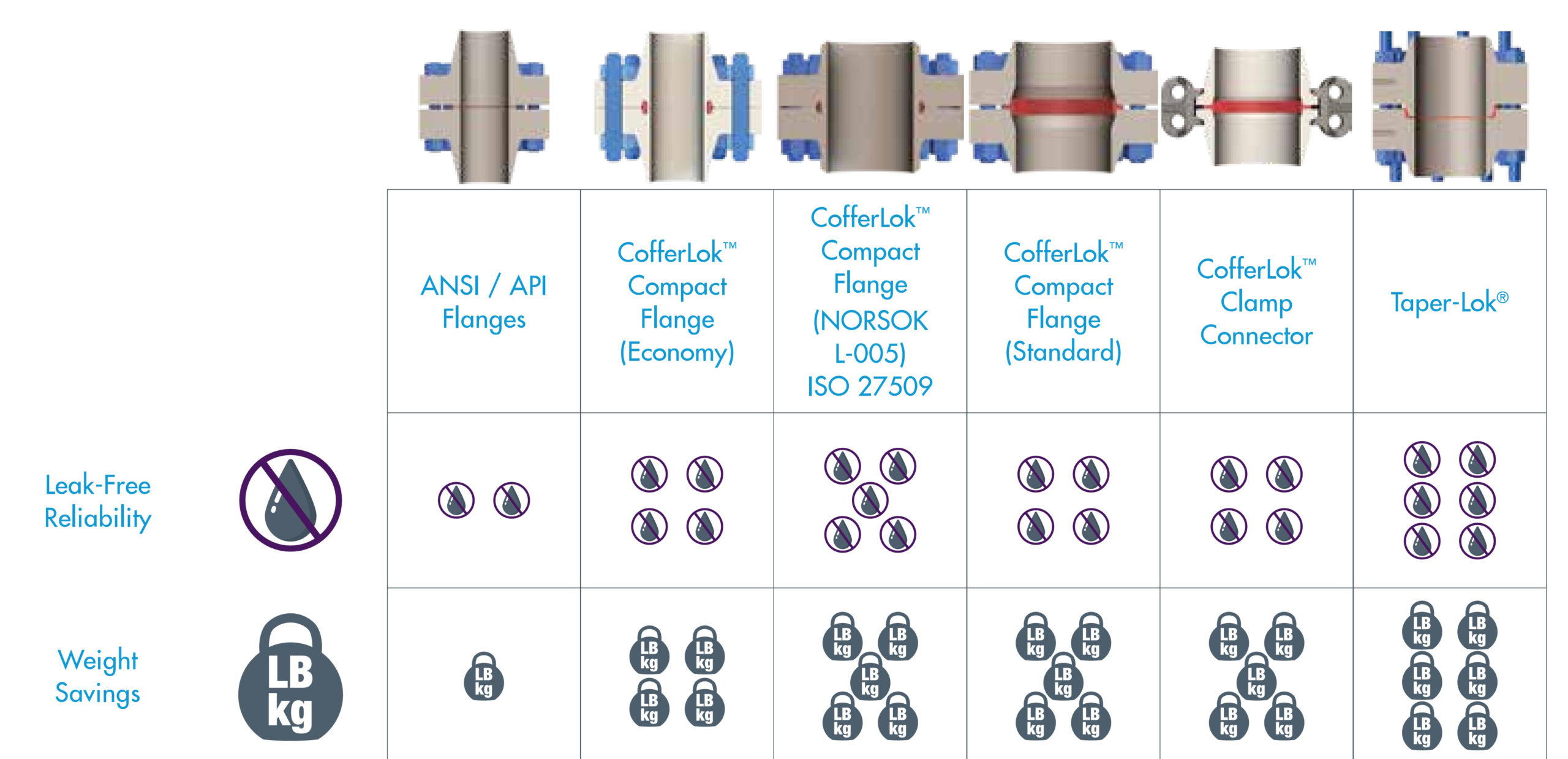

Connector Selection Chart

Choose the best connector for your project based on critical factors that are important to your specific process.